Transportation Cost Reduction in Supply Chain Management

9 Feb

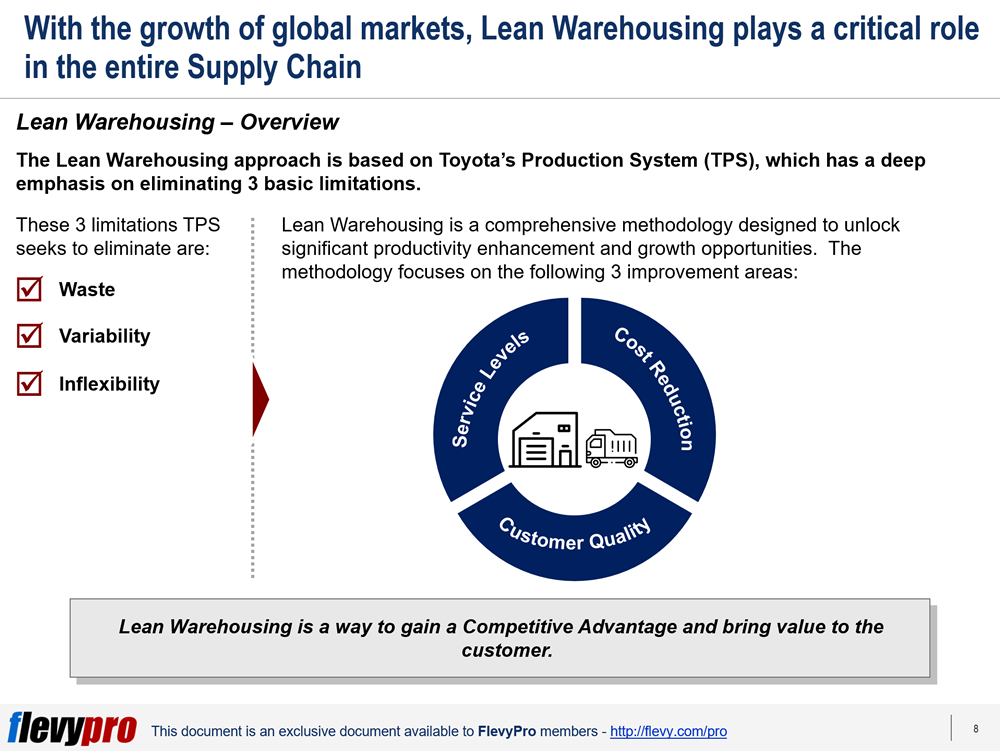

Companies looking to improve efficiency and reduce costs can gain significant ground in the Supply Chain Management function by incorporating Lean Management and Six Sigma techniques.

Reason this area has gone under the radar is that companies do not consider Supply Chain to be their core competency.

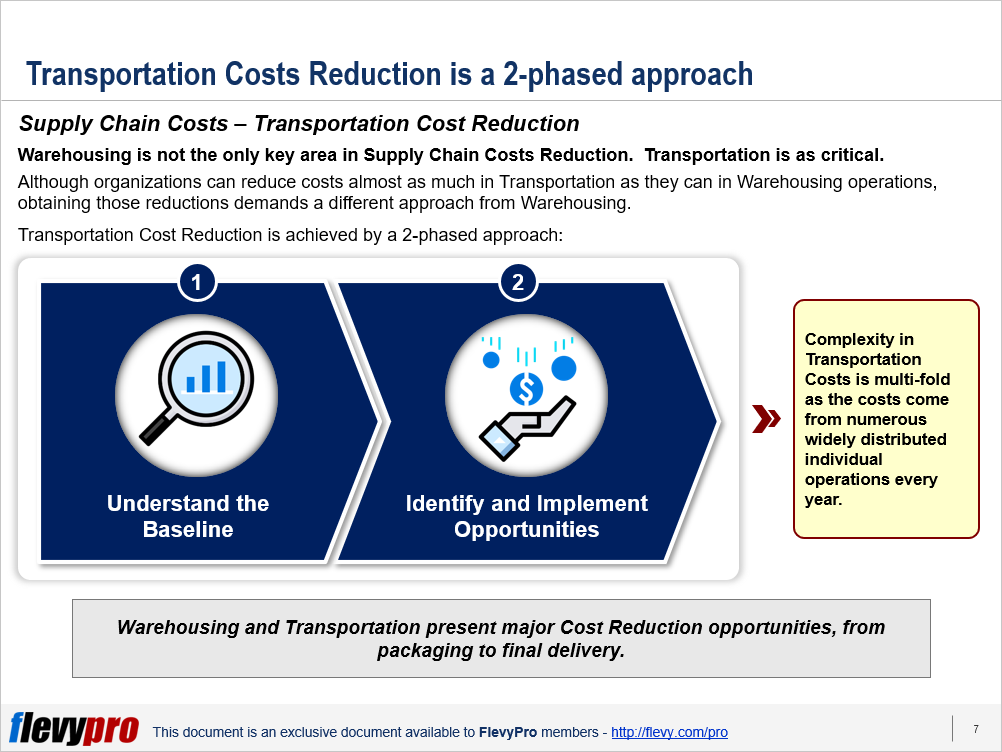

Not only Warehousing but Transportation also has almost the same potential in terms of opportunities for Cost Reduction and Process Improvement. The approach to Transportation Costs Reduction, though, is different to that of Supply Chain Cost Reduction in Warehousing. This is in part due to the complexity in Transportation Costs, as the costs come from numerous widely distributed individual operations every year.

The approach to Supply Chain Cost Reduction in Transportation encompasses 2 phases:

- Understand the Baseline

- Identify and Implement Opportunities

Let us delve a little deeper into the 2 phases.

1. Understand the Baseline

Improvement in Transportation operations is hindered, in most cases, by enormous variability in operations, diverse service levels being demanded by various customers, and a multitude of transport providers delivering services in a variety of ways.

Transportation Costs of between 20-30% can be saved by compiling a complete perspective of the overall Transportation operations of an organization. The evaluation will also reveal essential service categories that have a skewed effect on Cost.

2. Identify and Implement Opportunities

Identification of the Cost Drivers is imperative for the companies to develop a systematic approach to Transportation Cost Reduction. This systematic approach involves observing 4 main levers of Cost Optimization opportunities:

- Compliance with Contracted Price

- Negotiated Price

- Contract Terms

- Customer Breakpoints and Behavioral Changes

The 4 levers of Cost Reductions help in countering the issues impacting Transportation Costs and enabling significant savings.

Significant Cost Reductions can be gained by identifying mutual benefits and risks for both companies and suppliers in addition to understanding customer breakpoints that enable Customer Centric Design.

Let us consider a few instances where Cost Reduction can have a quick impact.

- Companies, often, have to pay substantial fuel surcharges for waiting time or late payments—caused by variance in actual delivery patterns and the delivery pattern specified in the contract.

- Suppliers usually charge a higher rate to compensate for inefficiencies in their operational structure. Understanding those inefficiencies helps identify significant savings potential.

- Logistics Service Providers either increase their rates or add fuel surcharges in order to protect themselves from the effect of fluctuating fuel prices. A fixed rate benefits the customer when fuel prices go up, but creates needless high fuel bills when prices are down.

- Ordering habits of certain customers add to the Transportation Costs. For example, unknowingly ordering early next-day deliveries, without an absolute necessity for it, causes significant (20% in some cases) extra cost than a delivery at noon. A 24-hour delivery time costs even less than the noon delivery.

Interested in learning more about the phases and cost drivers of Supply Chain Cost Reduction in Transportation? You can download an editable PowerPoint on Supply Chain Cost Reduction: Transportation here on the Flevy documents marketplace.

Want to Achieve Excellence in Supply Chain Management (SCM)?

Gain the knowledge and develop the expertise to become an expert in Supply Chain Management (SCM). Our frameworks are based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. Click here for full details.

Supply Chain Management (SCM) is the design, planning, execution, control, and monitoring of Supply Chain activities. It also captures the management of the flow of goods and services.

In February of 2020, COVID-19 disrupted—and in many cases halted—global Supply Chains, revealing just how fragile they have become. By April, many countries experienced declines of over 40% in domestic and international trade.

COVID-19 has likewise changed how Supply Chain Executives approach and think about SCM. In the pre-COVID-19 era of globalization, the objective was to be Lean and Cost-effective. In the post-COVID-19 world, companies must now focus on making their Supply Chains Resilient, Agile, and Smart. Additional trends include Digitization, Sustainability, and Manufacturing Reshoring.

Learn about our Supply Chain Management (SCM) Best Practice Frameworks here.

Do You Find Value in This Framework?

You can download in-depth presentations on this and hundreds of similar business frameworks from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives. Here’s what some have to say:

“My FlevyPro subscription provides me with the most popular frameworks and decks in demand in today’s market. They not only augment my existing consulting and coaching offerings and delivery, but also keep me abreast of the latest trends, inspire new products and service offerings for my practice, and educate me in a fraction of the time and money of other solutions. I strongly recommend FlevyPro to any consultant serious about success.”

– Bill Branson, Founder at Strategic Business Architects

“As a niche strategic consulting firm, Flevy and FlevyPro frameworks and documents are an on-going reference to help us structure our findings and recommendations to our clients as well as improve their clarity, strength, and visual power. For us, it is an invaluable resource to increase our impact and value.”

– David Coloma, Consulting Area Manager at Cynertia Consulting

“FlevyPro has been a brilliant resource for me, as an independent growth consultant, to access a vast knowledge bank of presentations to support my work with clients. In terms of RoI, the value I received from the very first presentation I downloaded paid for my subscription many times over! The quality of the decks available allows me to punch way above my weight – it’s like having the resources of a Big 4 consultancy at your fingertips at a microscopic fraction of the overhead.”

– Roderick Cameron, Founding Partner at SGFE Ltd