Lean Product Development & Innovation

8 Aug

Improving Product Development competencies in designers and developers is a concern for senior leaders in the manufacturing sector.

The approach most organizations take in developing Human Resources does not go beyond staffing the cream of the crop from leading global educational institutes. Talent Development to them is, typically, sending their people to attend workshops and keeping up with employee annual training hours’ goals, and that’s it. Companies usually spend more on acquiring latest manufacturing equipment or modern collaboration tools than they do to develop their greatest asset—their people.

Research on manufacturing practices unequivocally suggests that it’s primarily the inspiration to adopt a culture of Continuous Improvement in people that results in operational excellence. This Continuous Improvement Culture has more significance than implementing Lean practices across all processes.

The “Lean Product Development” concept isn’t a new notion. The practice has been around since the 1980s. An MIT study in the 1980s revealed that manufacturing practices in Japanese automakers were totally opposed to those of auto manufacturers in the rest of the world. These approaches were referred to as “Lean” practices. Research into manufacturing practices of Toyota has spread the knowledge about Lean Product Development globally.

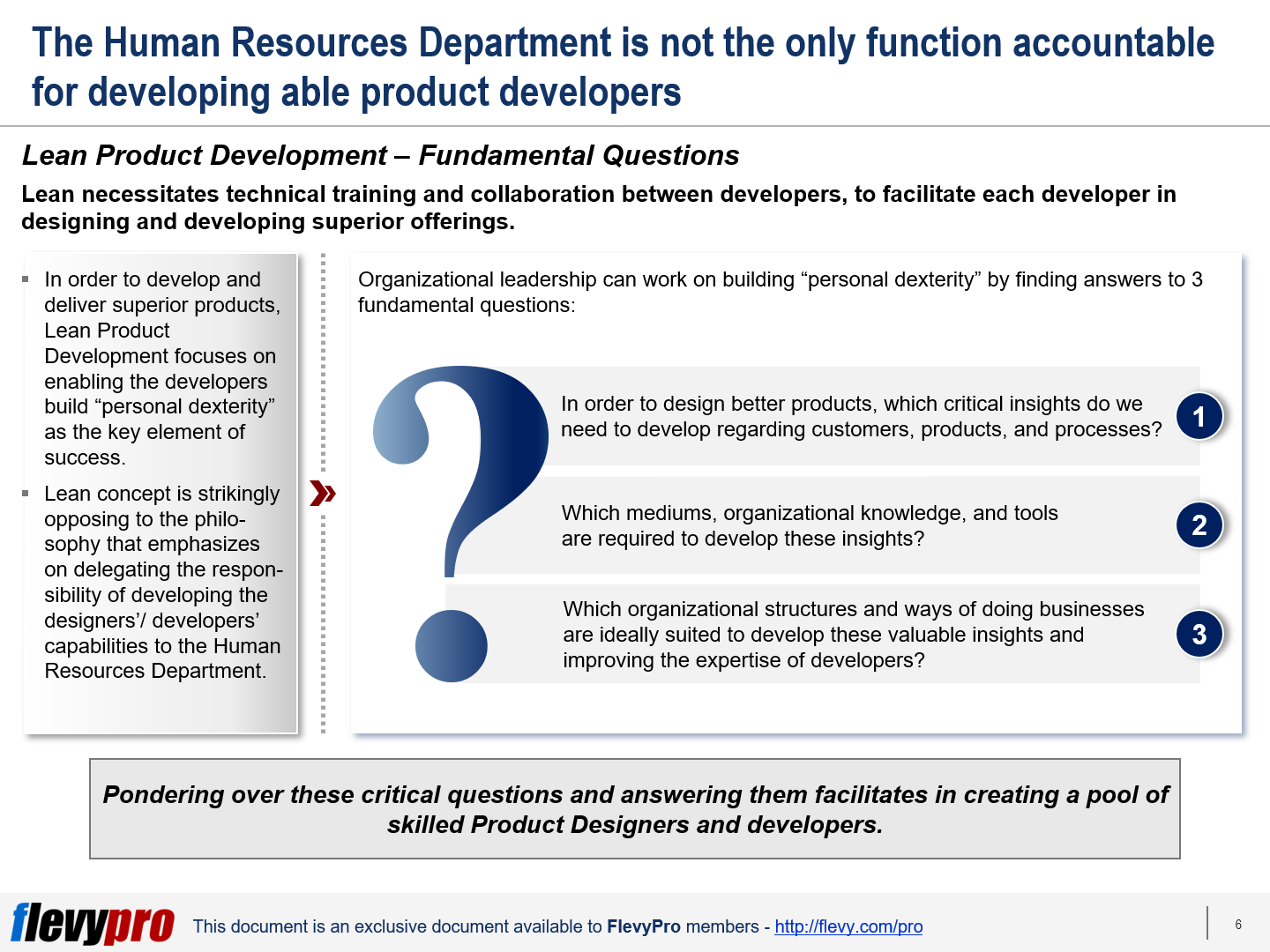

Lean concept is strikingly opposing to the philosophy that emphasizes on delegating the responsibility of developing the designers’ / developers’ capabilities to the Human Resources Department. In order to develop and deliver superior products, Lean Product Development focuses on enabling the developers build “personal dexterity” as the key element of success. The concept necessitates technical training and collaboration between developers.

Before embarking on the Lean Product Development and Innovation journey, organizational leadership should work on finding answers to these 3 fundamental questions:

- In order to design better products, which critical insights do we need to develop regarding customers, products, and processes?

- Which mediums, organizational knowledge, and tools are required to develop these insights?

- Which organizational structures and ways of doing businesses are ideally suited to develop these valuable insights and improving the expertise of developers?

Pondering over these critical questions and answering them facilitates in creating a pool of skilled Product Designers and developers.

Let’s dive deeper into these questions.

Question 1

Lean Product Development emphasizes on developing a steady stream of products at an even pace—referred to as “Takt.” iPhone 1 and iPhone 2 are examples of a steady stream of products released at regular intervals in Apple’s iPhone value stream.

Takt has evolved the way products are designed. An initial product is developed as a means to validate an idea. Products are progressed from the initial product based on stakeholders’ feedback. The purpose of a value stream of products is to improve the current product offerings, inspire the existing customers to upgrade, and tempt potential customers to try the product. In these evolving value streams, every product release serves as an opportunity to gain insights into the market.

The value enhancement through Takt has 2 broad objectives:

- Fixing problems in existing products and creating offerings meeting the customer needs.

- Lowering manufacturing costs and improving quality.

Question 2

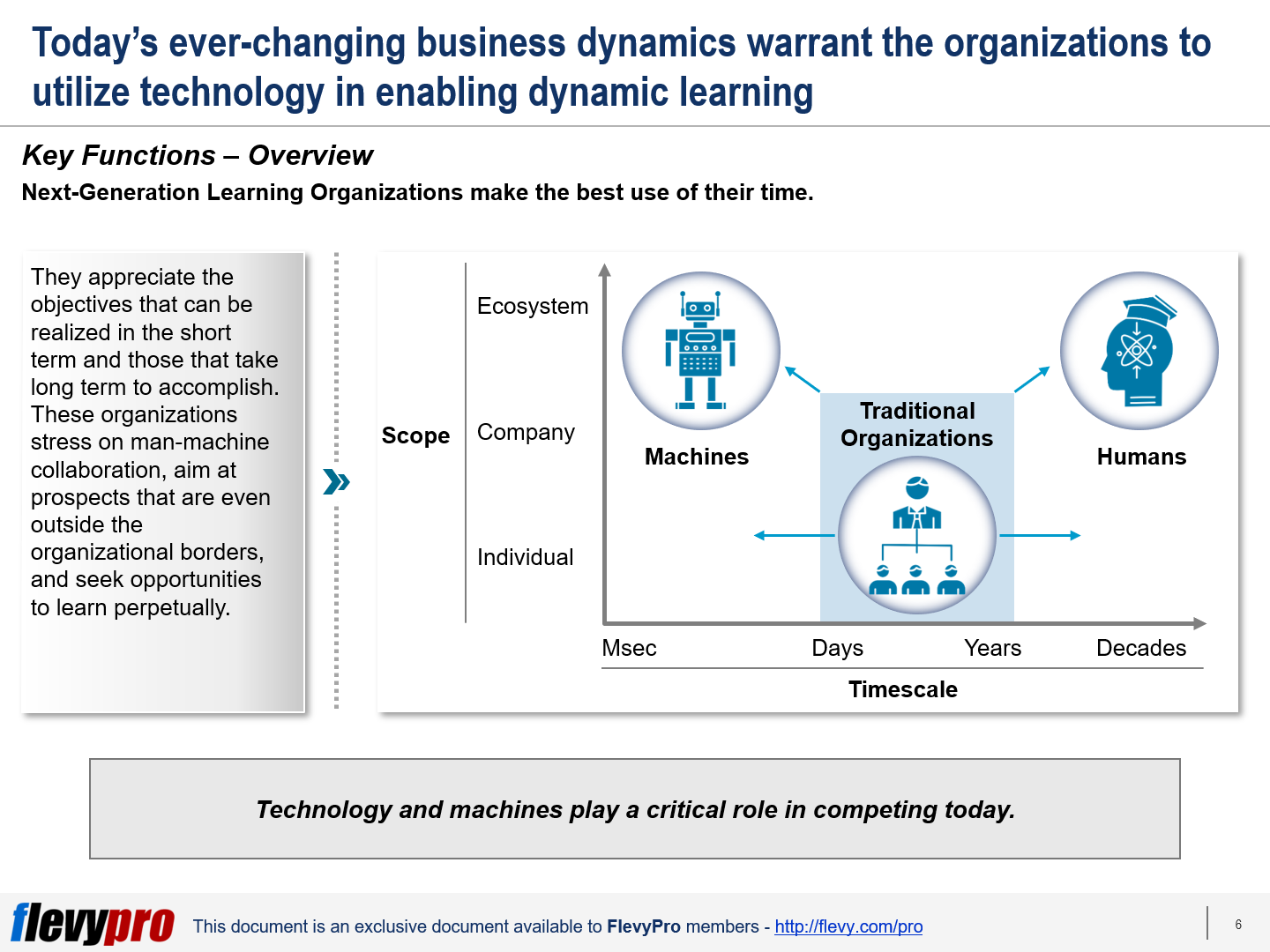

Lean Product Development underscores the significance of the medium through which developers should learn in order to create superior products. Developers’ capabilities in technical Problem Solving and learning what the others are doing helps enhance the quality of each new release. Development teams should have quick access to accumulating a thorough knowledge of the entire supply chain and the effect of their decisions on manufacturing. This assists in improving the efficiency of the developers.

Instead of learning and gaining knowledge through traditional ways, Lean Product Development encourages the developers to learn through Action Learning—the process where teams are continuously mentored and encouraged to learn collectively on the job, solve problems creatively, and test models to cope with real-life issues.

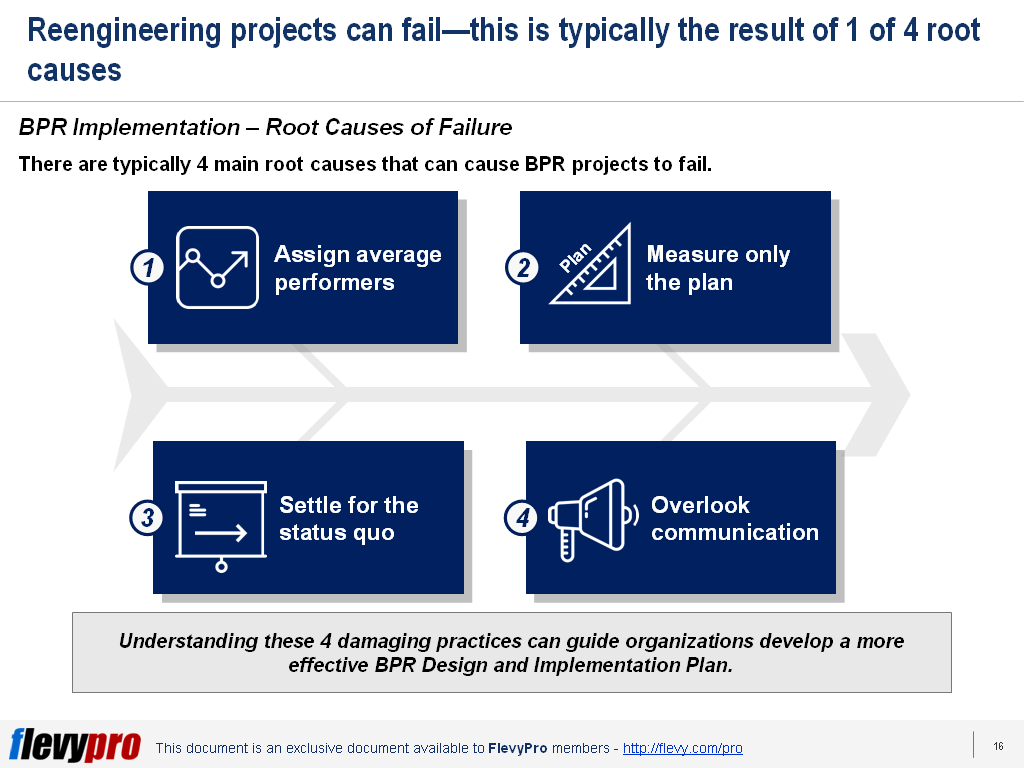

Interested in learning more about the key elements to consider before enabling Lean Product Development & Innovation, and the phases of the Lean process? You can download an editable PowerPoint on Lean Product Development & Innovation here on the Flevy documents marketplace.

Did You Find Value in This Framework?

You can download in-depth presentations on this and hundreds of similar business frameworks from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives. Here’s what some have to say:

“My FlevyPro subscription provides me with the most popular frameworks and decks in demand in today’s market. They not only augment my existing consulting and coaching offerings and delivery, but also keep me abreast of the latest trends, inspire new products and service offerings for my practice, and educate me in a fraction of the time and money of other solutions. I strongly recommend FlevyPro to any consultant serious about success.”

– Bill Branson, Founder at Strategic Business Architects

“As a niche strategic consulting firm, Flevy and FlevyPro frameworks and documents are an on-going reference to help us structure our findings and recommendations to our clients as well as improve their clarity, strength, and visual power. For us, it is an invaluable resource to increase our impact and value.”

– David Coloma, Consulting Area Manager at Cynertia Consulting

“FlevyPro has been a brilliant resource for me, as an independent growth consultant, to access a vast knowledge bank of presentations to support my work with clients. In terms of RoI, the value I received from the very first presentation I downloaded paid for my subscription many times over! The quality of the decks available allows me to punch way above my weight – it’s like having the resources of a Big 4 consultancy at your fingertips at a microscopic fraction of the overhead.”

– Roderick Cameron, Founding Partner at SGFE Ltd